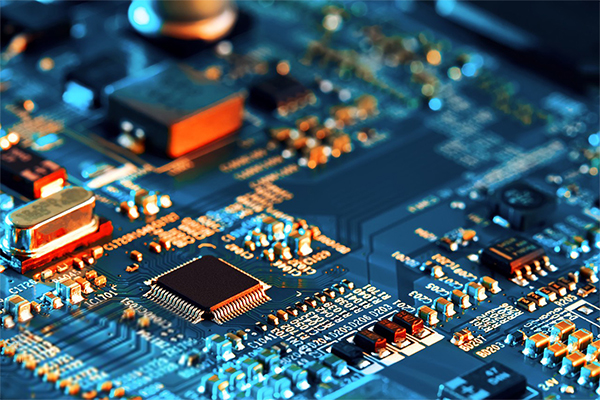

SemiConductor / Electronics

Ama-semiconductors asetshenziswa kumasekethe ahlanganisiwe, ama-electronics abathengi, izinhlelo zokuxhumana, ukukhiqizwa kwamandla e-photovoltaic, ukukhanyisa, ukuguqulwa kwamandla aphezulu kanye nezinye izinkambu. Kungakhathaliseki ukuthi ngokombono wezobuchwepheshe noma ukuthuthukiswa komnotho, ukubaluleka kwama-semiconductors kukhulu. Izinto ezivamile ze-semiconductor zifaka i-silicon, i-germanium, i-gallium arsenide, njll., futhi i-silicon iyona enethonya elikhulu ekusetshenzisweni kwezinto ezihlukahlukene ze-semiconductor.

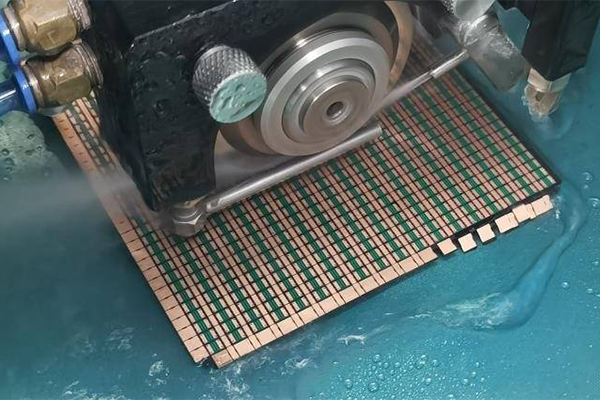

Umshini Wokubhala Ocekeceke ☞

Ukubhalwa kwe-Silicon wafer kuyisinyathelo sokuqala senqubo yokuhlanganisa "emuva" futhi kuyisixhumanisi esibalulekile ekwenziweni kwe-semiconductor. Le nqubo ihlukanisa i-wafer ibe ama-chips ngamanye ukuze kuhlanganiswe i-chip, i-lead bonding, kanye nemisebenzi yokuhlola.

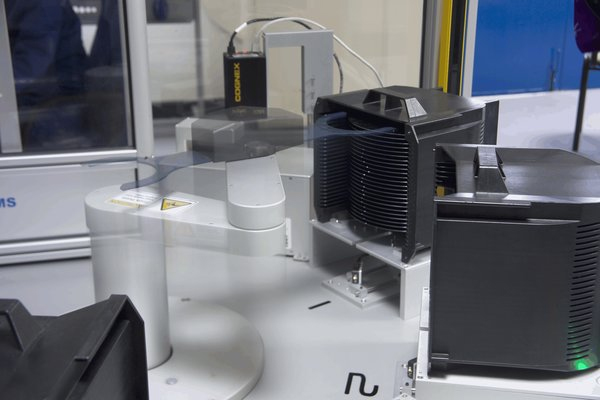

I-Wafer Sorter ☞

Isihlungi se-wafer singahlukanisa futhi siqoqe amawafa akhiqiziwe ngokuya ngemingcele yawo yosayizi njengobubanzi noma ukujiya ukuze ahlangabezane nezidingo zokukhiqiza zemikhiqizo ehlukene noma izinqubo; Ngesikhathi esifanayo, ama-wafers anesici ayahlolwa ukuze kuqinisekiswe ukuthi ama-wafers afanelekayo kuphela angena esinyathelweni esilandelayo sokucubungula nokuhlola.

Izisetshenziswa zokuhlola ☞

Ekukhiqizeni amadivaysi e-semiconductor, inqwaba noma amakhulu ezinqubo kufanele atholakale kusukela ku-semiconductor single wafer kuya kumkhiqizo wokugcina. Ukuze kuqinisekiswe ukuthi ukusebenza komkhiqizo kuyafaneleka, kuzinzile futhi kunokwethenjelwa, futhi kunesivuno esikhulu, ngokwesimo sokukhiqizwa kwemikhiqizo ehlukahlukene, kufanele kube nezidingo eziqinile eziqondile kuzo zonke izinyathelo zenqubo. Ngakho-ke, amasistimu ahambisanayo kanye nezinyathelo zokuqapha ezinembile kufanele zisungulwe enqubweni yokukhiqiza, kusukela ekuhlolweni kwenqubo ye-semiconductor kuqala.